Boost supply chain agility with advanced planning and forecasting

Is your supply chain set up to support growth? Find out about the importance of a responsive supply chain plan and how to achieve it.

Boost supply chain agility with advanced planning and forecasting

Is your supply chain set up to support growth? Find out about the importance of a responsive supply chain plan and how to achieve it.

Table of contents

Table of contents

Key points

Responding to the market: the supply chain dilemma

Volatility, uncertainty and risk are undeniable, consistent market characteristics for organizations of all kinds — and they’re not going away anytime soon. If we’re being honest about business planning, it is a rare day that everything goes exactly according to plan. That’s why the name of today’s game is agility. The organization set up to be flexible and responsive is the organization set up to succeed. An organization that cannot respond to the needs of its customers is committing a major faux pas, driving customer dissatisfaction and, inevitably, lost sales. Leading organizations are implementing a more fluid work structure made up of cross-functional teams with higher visibility and operational efficiency. For many, the inspiration to do so is a desire to get closer and become more responsive to their customers. This is an especially relevant goal for supply chain management.

Supply chain management covers the crucial tasks of managing the overall operational plan, management of day-to-day operations and forecasting demand for the future. In essence, these activities ensure customers are kept happy by receiving quality products on time. Supply chain management is a key driver in corporate strategic planning and is essential for the firm to include in their financial planning. A well-oiled supply chain drives productivity and profitability for the company with accurate demand planning and the ability to penetrate new and existing markets, where success is also driven by tight coordination across the organization with marketing, HR, finance, and sales, etc.

Still, many obstacles can get in the way of a collaborative, efficient and effective planning process. Inability to create sound forecasts leaves organizations without the budget or inventory to meet customer needs. Availability and on-time delivery of goods is crucial to ensure business continuity. Above all, running a smooth, efficient supply chain is key.

Barriers to effective supply chain planning

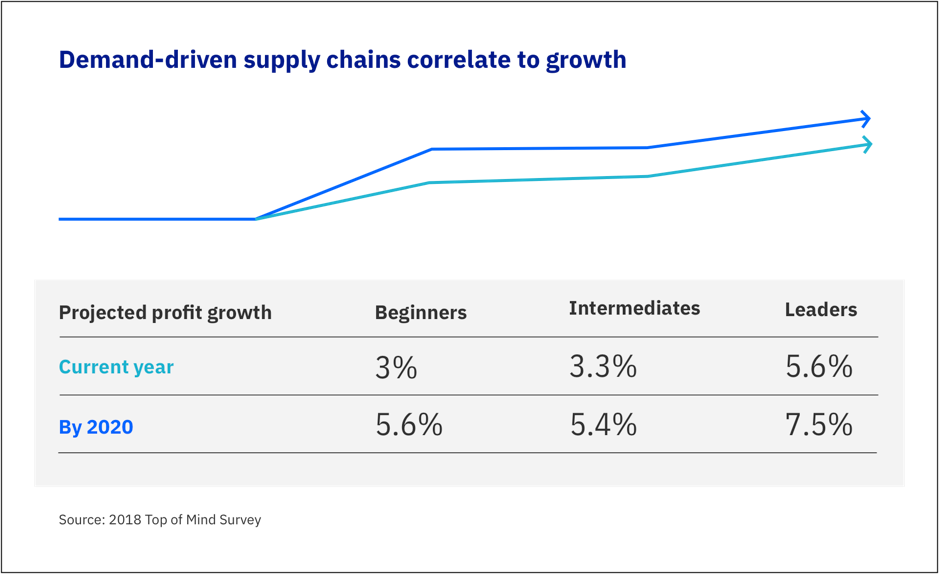

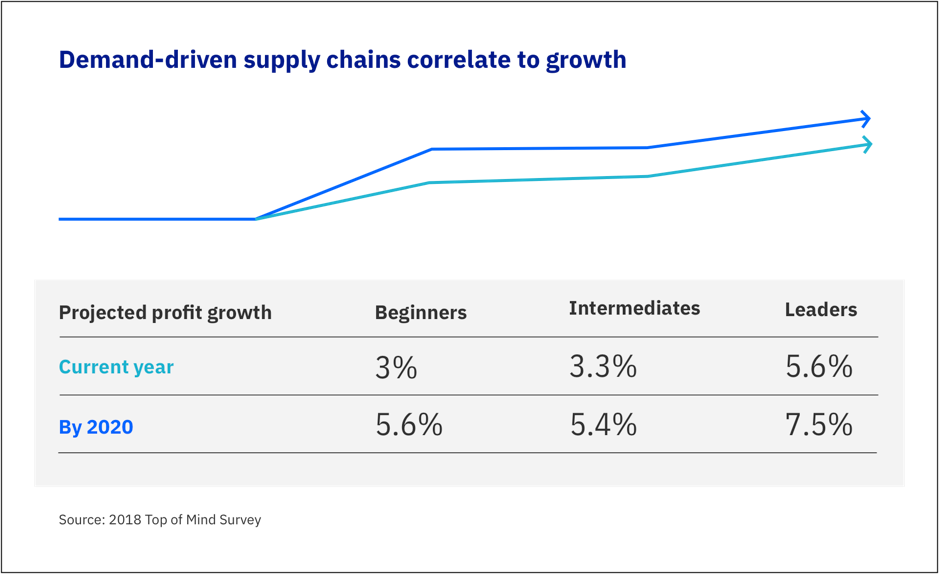

Supply and demand planning correlate directly with organizational growth. The risks of inaccurate forecasting are far too great when the importance of customer satisfaction is non-negotiable. The ability of an organization to gain market share depends greatly on the ability to stay ahead — of the technology curve, competition and customer experience.

Obstacles to supply chain management are rampant and come in multiple forms, including:

- Difficulty optimizing the allocation of resources, e.g., manpower and time

- Siloed and underutilized data, resulting in misalignment of expectation and execution

- Inability to quickly evaluate and respond to supply chain disruption and market changes

Resource alignment challenges

You need the time and manpower to accurately assess what’s driving your business.

Spreadsheets are a popular tool among planning professionals. Though they’re useful for individual analysis, they have major shortcomings when it comes to large-scale planning, budgeting, forecasting and manipulating large data sets.

5 Spreadsheet hazards

Aside from outright errors, spreadsheets can present other limitations and drawbacks when organizations try to use them for large-scale performance management.

- 1. Little standardization in the planning process → Wasted time

- 2. Lack of data integrity and transparency → Conflicting versions of the truth

- 3. Lack of collaboration → Missing insights from the front lines of the business

- 4. Slow process to collect and verify data → Inability to react quickly to changes

- 5. Aggregation and application maintenance → Spreadsheets painful to maintain

Unfortunately, too many supply chain professionals are busy spending all their time manually digging for data and cobbling together spreadsheets when they ought to be analyzing data and creating recommendations that will improve supply chain efficiency. Manual data collection and validation adds hours or even days of additional labor, leading to unnecessarily long planning cycles.

75 percent of companies fail to execute on their strategy because they are unable to coordinate and align resources. 1

—Charles Sull, Donald Sull, Rebecca Homkes, "Why Strategy Execution Unravels — and What to Do About It," Harvard Business Review, March 2015

Overstocking and slow turnaround times for order fulfillment are not acceptable. Leadership needs an accurate and complete picture of costs and inventory in order to ensure that supply chain plans align with corporate and operational objectives. Few have (or should even consider) the extra time and people needed to coordinate disparate spreadsheets.

You need a solution that automates processes for quicker, more accurate insights in a repeatable manner. That’s just the beginning — even if you’re equipped with good data, you still need the ability to clearly and easily pinpoint trends by slicing and dicing it in exactly the right way, without the manual number-crunching. Tools that automate and visualize data help you understand exactly what you’re looking at, reducing the risk of flawed planning and inaccurate reporting.

“ If you don’t get your models and your insights systematically connected with the business decision-making process, then you’re isolated. ”

–Donald Neumann, PHD, Demand Manager at Grupo Boticário

Many finance and operations teams spend as much as 60 - 70 percent of their time on data collection and validation instead of on value-added analysis to support the business. 2

—Keith Button, CFO Magazine article “FP&A – Let the Fun Begin”, Nov 2, 2017

The problem with poor data

Siloed and inaccessible, poor data can lead to big problems.

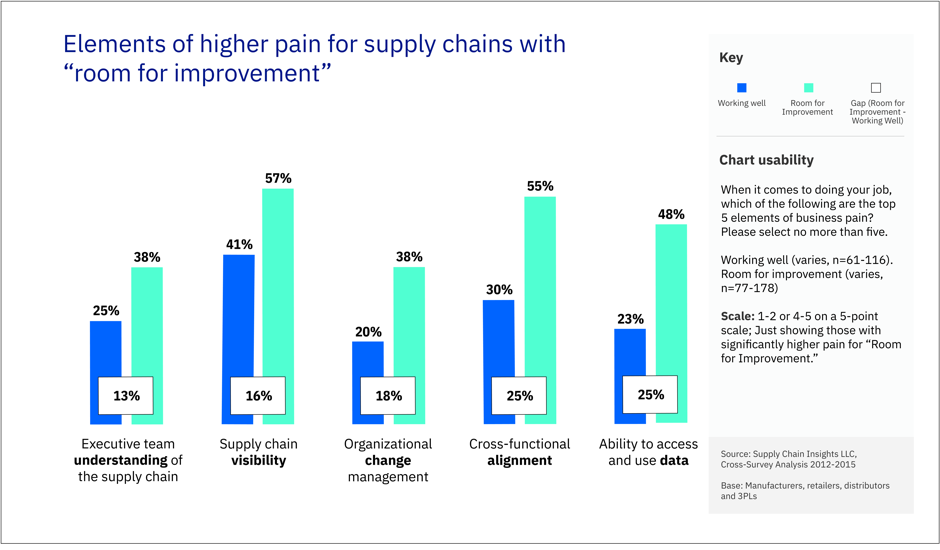

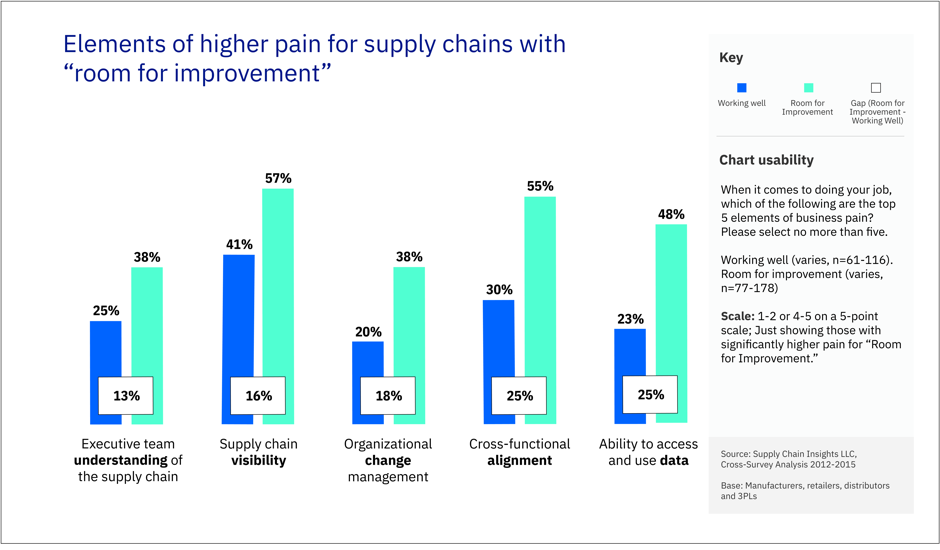

Oceans of data often translates to an organization being data-rich but insights-poor. There may be a massive volume of stored information, but it languishes in disparate systems where it’s unintegrated and inaccessible to the right people. In fact, 57 percent of supply chain professionals say there is room for improvement when it comes to supply chain visibility. Why did our inventory estimate end up so far off? How have we managed a challenge like this in the past? If you can’t get the data you need quickly, you can’t plan appropriately for the future. And you surely can’t answer the questions from leadership about exactly why it happened.

Break down the silos in your data to get the full picture of your supply chain operations to take the lead over organizations without visibility.

An overreliance on spreadsheets also opens your data up to increasing error rates. In addition to the time-consuming nature of circulating spreadsheets, manual processes almost guarantee that errors will be introduced.

The right solution gives you simple, real-time, visual insights into your data and the potential impact of your decisions, helping you avoid the high-cost mistakes.

According to Gartner, the average financial impact of poor data on business is $9.7 million per year. 3

—Forbes Insights “The Data Differentiator – How Improving Data Quality Improves Business” 2017

Why agility matters

Respond quickly to change or risk broken links in the supply chain that can lead to customer dissatisfaction.

You’re thrown a curve ball — it happens to everyone. Your budget is cut, a natural disaster disables a key supply source, or demand suddenly skyrockets due to market shifts. You need to be able to react fast. It’s important to access your data in real time and get the most accurate picture of your current situation. But you also need to smoothly pivot and change your existing plans. You need to understand how new scenarios will play out against current circumstances so you can take the best course of action.

Dynamic changes pose another challenge to the spreadsheet model. It’s wishful thinking to assume you can effectively make a change across a 50-tab worksheet and multiple departments. The margin for error is too high. Instead, make a simple change in one place that dynamically updates every outcome relying on that single variable. Enable real-time collaboration between lines of business and make changes fast based on one source of truth.

“ Digital supply networks overcome the delayed action-reaction process of the linear supply chain by employing real-time data to better inform decisions, provide greater transparency, and enable enhanced collaboration across the entire supply network. ”

-“The Rise of the Digital Supply Chain Network”, Deloitte University Press. Published December 1, 2016.

When the curve balls come, you need to weigh your options. If you can’t assess different scenarios quickly to understand how each one would impact your business, you risk crippling your supply chain.

In the supply chain planning environment, agility often means the ability to quickly pivot to meet changing customer demands. When an organization cannot be responsive, they risk unfulfilled orders or sub-standard product quality. The ability to flex and change with market demands is a critical part of forward-thinking supply chain management DNA.

There’s a better way

Add automation, deep insights, and agility to your planning — it’s called IBM Planning Analytics powered by IBM TM1®.

Spend more time on what matters

Instead of spending about 65 percent of your time in collecting data, you can automate much of the process. This enables you to focus on value-added planning, forecasting, reporting and analysis to deliver fast, optimized insights. Use one single planning solution wherein all your different lines of business can collaborate. This shared solution is dynamic and provides a single version of the truth across your organization. It’s accessible and the data is easy to interact with, reducing reliance on IT staff to help create and manage advanced models. The entire organization can use one tool to submit and analyze data and create accurate plans and forecasts. Choose from a range of visualization options to share informative scorecards, dashboards and reports with stakeholders.

Be an analytical captain on your data ocean

Remember that solution we mentioned? It’s not only ideal for collaboration, it’s great for analyzing a ton of data hosted on the IBM TM1 Server. This will give you the ability to integrate all of your data warehouses (CRM, ERP, etc.) to deliver a full picture of what’s going on in your supply chain. And it’s a pretty picture, at that. The simple, easy-to-use, self-service interface gives you the ability to analyze and visualize results and identify trends to inform decisions. The solution can identify insights automatically, directly from your data, to apply to the planning and analytics process. Plus, with everyone using the same solution, you limit the possibility of erroneous formulas and mismatched numbers. You also have the ability to perform complex dimensional analysis to go deep into your numbers and understand the implications of changes.

Be ready for anything

We all know plans change. But with the right tool, your plans can be automatically adjusted as needed to meet changing supply-demand requirements. This helps you react faster to changing market conditions or unexpected impacts on your supply chain. You can easily weigh your options and quickly conduct unlimited what-if scenario analyses to discover how to optimize business outcomes. Just a few clicks and you’ll see how one change will impact each part of your supply chain, including sales and profit modeling.

Gartner predicted that by 2020, at least 25 percent of large organizations will increase planning accuracy by integrating key operational planning processes with financial planning and analysis. 4

—Gartner Predicts 2018: SaaS Financial Management Applications Increase Integration, Automation and Sophistication, Gartner, 2017.

Why IBM?

With IBM Planning Analytics, you can go beyond automation to optimize supply chain performance with advanced planning and forecasting capabilities. The solution is built to drive business success through lean operations, inventory optimization, material management, waste reduction and working capital optimization. And with this scalable solution available on premises or in the cloud, you can choose the deployment that fits your needs and scale up as your needs grow.

Plus, IBM Planning Analytics provides the ability to:

- Automate and streamline planning, budgeting and forecasting processes

- Perform unlimited what-if scenario analysis to take effective action

- Achieve real-time, detailed visibility into key inventory control and supply chain management metrics

- Perform complex multi-dimensional analysis and calculations

- Automatically create and deliver new insights directly from data for more reliable plans and forecasts

- Leverage an interactive, customizable planning and analytics workspace to measure and monitor performance, evaluate plans, identify gaps and diagnose root causes

- Have the option to work in the familiar Microsoft Excel interface with minimal learning curve while enjoying all the capabilities of a modern planning and analytics solution

Client stories

You don’t have to take it from us – find out how our clients are succeeding with IBM Planning Analytics:

Allen Edmonds

IBM Planning Analytics is helping Allen Edmonds evolve into a smarter business to provide better service to customers and optimize inventory and costs.

Outcomes:

- 50 percent faster reporting, saving one day per week on weekly strategic planning

- 10 percent lift in forecasting accuracy

“ Our reporting processes are at least 50 percent faster now, which has a real positive impact on the way we do business. ”

–Connie Walsh, Director of Retail Inventory, Planning and Analysis, Allen Edmonds

Rotkäppchen-Mumm

IBM Planning Analytics to optimize the production of product quantities based on accurate insights into demand and future trends.

Outcomes:

- 22 percent increase in accuracy of selected sales forecasts

- Reduces stock levels without increasing the risk of stockouts

“ The ability to access IBM Planning Analytics from any device enables us to work on the move, spend more time with business users out in the field and work much more flexibly and productively. ”

– André Birrenbach, Chief Information Officer, Rotkäppchen-Mumm

Fleetpride

IBM Planning Analytics to give supply chain managers game-changing insights into operations. It has helped them to improve the efficiency of the entire supply chain.

Outcomes:

- 99.5 percent of warehouse packing tasks are now error-free

- Accelerates inventory movement, reducing labor costs and increasing revenues

“ Line managers all have quick, easy access to the latest operational data via detailed reports that help them to make smarter, more-informed decisions to improve the efficiency of the entire supply chain. ”

– Homarjun Agrahari, Director, Advanced Analytics, FleetPride

Next steps

See if IBM Planning Analytics is right for you

Hungry for more? Explore all the features available to you.

See IBM Planning Analytics in action

Experience this interactive demo to get a real taste of functionality.

Download PDF

Download the PDF version of this white paper.

Sources

- Charles Sull, Donald Sull, Rebecca Homkes, "Why Strategy Execution Unravels -- and What to Do About It," Harvard Business Review, March 2015

- Keith Button, CFO Magazine article “FP&A – Let the Fun Begin”, Nov 2, 2017

- Forbes Insights “The Data Differentiator – How Improving Data Quality Improves Business” 2017

- Gartner Predicts 2018: SaaS Financial Management Applications Increase Integration, Automation and Sophistication, Gartner, 2017.

Table of contents

Responding to the market: the supply chain dilemma

Responding to the market: the supply chain dilemma

Volatility, uncertainty and risk are undeniable, consistent market characteristics for organizations of all kinds — and they’re not going away anytime soon. If we’re being honest about business planning, it is a rare day that everything goes exactly according to plan. That’s why the name of today’s game is agility. The organization set up to be flexible and responsive is the organization set up to succeed. An organization that cannot respond to the needs of its customers is committing a major faux pas, driving customer dissatisfaction and, inevitably, lost sales. Leading organizations are implementing a more fluid work structure made up of cross-functional teams with higher visibility and operational efficiency. For many, the inspiration to do so is a desire to get closer and become more responsive to their customers. This is an especially relevant goal for supply chain management.

Supply chain management covers the crucial tasks of managing the overall operational plan, management of day-to-day operations and forecasting demand for the future. In essence, these activities ensure customers are kept happy by receiving quality products on time. Supply chain management is a key driver in corporate strategic planning and is essential for the firm to include in their financial planning. A well-oiled supply chain drives productivity and profitability for the company with accurate demand planning and the ability to penetrate new and existing markets, where success is also driven by tight coordination across the organization with marketing, HR, finance, and sales, etc.

Still, many obstacles can get in the way of a collaborative, efficient and effective planning process. Inability to create sound forecasts leaves organizations without the budget or inventory to meet customer needs. Availability and on-time delivery of goods is crucial to ensure business continuity. Above all, running a smooth, efficient supply chain is key.

Barriers to success

Barriers to effective supply chain planning

Supply and demand planning correlate directly with organizational growth. The risks of inaccurate forecasting are far too great when the importance of customer satisfaction is non-negotiable. The ability of an organization to gain market share depends greatly on the ability to stay ahead — of the technology curve, competition and customer experience.

Obstacles to supply chain management are rampant and come in multiple forms, including:

- Difficulty optimizing the allocation of resources, e.g., manpower and time

- Siloed and underutilized data, resulting in misalignment of expectation and execution

- Inability to quickly evaluate and respond to supply chain disruption and market changes

Resource alignment challenges

Resource alignment challenges

You need the time and manpower to accurately assess what’s driving your business.

Spreadsheets are a popular tool among planning professionals. Though they’re useful for individual analysis, they have major shortcomings when it comes to large-scale planning, budgeting, forecasting and manipulating large data sets.

5 Spreadsheet hazards

Aside from outright errors, spreadsheets can present other limitations and drawbacks when organizations try to use them for large-scale performance management.

- 1. Little standardization in the planning process → Wasted time

- 2. Lack of data integrity and transparency → Conflicting versions of the truth

- 3. Lack of collaboration → Missing insights from the front lines of the business

- 4. Slow process to collect and verify data → Inability to react quickly to changes

- 5. Aggregation and application maintenance → Spreadsheets painful to maintain

Unfortunately, too many supply chain professionals are busy spending all their time manually digging for data and cobbling together spreadsheets when they ought to be analyzing data and creating recommendations that will improve supply chain efficiency. Manual data collection and validation adds hours or even days of additional labor, leading to unnecessarily long planning cycles.

75 percent of companies fail to execute on their strategy because they are unable to coordinate and align resources. 1

—Charles Sull, Donald Sull, Rebecca Homkes, "Why Strategy Execution Unravels — and What to Do About It," Harvard Business Review, March 2015

Overstocking and slow turnaround times for order fulfillment are not acceptable. Leadership needs an accurate and complete picture of costs and inventory in order to ensure that supply chain plans align with corporate and operational objectives. Few have (or should even consider) the extra time and people needed to coordinate disparate spreadsheets.

You need a solution that automates processes for quicker, more accurate insights in a repeatable manner. That’s just the beginning — even if you’re equipped with good data, you still need the ability to clearly and easily pinpoint trends by slicing and dicing it in exactly the right way, without the manual number-crunching. Tools that automate and visualize data help you understand exactly what you’re looking at, reducing the risk of flawed planning and inaccurate reporting.

“ If you don’t get your models and your insights systematically connected with the business decision-making process, then you’re isolated. ”

–Donald Neumann, PHD, Demand Manager at Grupo Boticário

Many finance and operations teams spend as much as 60 - 70 percent of their time on data collection and validation instead of on value-added analysis to support the business. 2

—Keith Button, CFO Magazine article “FP&A – Let the Fun Begin”, Nov 2, 2017

The problem with poor data

The problem with poor data

Siloed and inaccessible, poor data can lead to big problems.

Oceans of data often translates to an organization being data-rich but insights-poor. There may be a massive volume of stored information, but it languishes in disparate systems where it’s unintegrated and inaccessible to the right people. In fact, 57 percent of supply chain professionals say there is room for improvement when it comes to supply chain visibility. Why did our inventory estimate end up so far off? How have we managed a challenge like this in the past? If you can’t get the data you need quickly, you can’t plan appropriately for the future. And you surely can’t answer the questions from leadership about exactly why it happened.

Break down the silos in your data to get the full picture of your supply chain operations to take the lead over organizations without visibility.

An overreliance on spreadsheets also opens your data up to increasing error rates. In addition to the time-consuming nature of circulating spreadsheets, manual processes almost guarantee that errors will be introduced.

The right solution gives you simple, real-time, visual insights into your data and the potential impact of your decisions, helping you avoid the high-cost mistakes.

According to Gartner, the average financial impact of poor data on business is $9.7 million per year. 3

—Forbes Insights “The Data Differentiator – How Improving Data Quality Improves Business” 2017

Why agility matters

Why agility matters

Respond quickly to change or risk broken links in the supply chain that can lead to customer dissatisfaction.

You’re thrown a curve ball — it happens to everyone. Your budget is cut, a natural disaster disables a key supply source, or demand suddenly skyrockets due to market shifts. You need to be able to react fast. It’s important to access your data in real time and get the most accurate picture of your current situation. But you also need to smoothly pivot and change your existing plans. You need to understand how new scenarios will play out against current circumstances so you can take the best course of action.

Dynamic changes pose another challenge to the spreadsheet model. It’s wishful thinking to assume you can effectively make a change across a 50-tab worksheet and multiple departments. The margin for error is too high. Instead, make a simple change in one place that dynamically updates every outcome relying on that single variable. Enable real-time collaboration between lines of business and make changes fast based on one source of truth.

“ Digital supply networks overcome the delayed action-reaction process of the linear supply chain by employing real-time data to better inform decisions, provide greater transparency, and enable enhanced collaboration across the entire supply network. ”

-“The Rise of the Digital Supply Chain Network”, Deloitte University Press. Published December 1, 2016.

When the curve balls come, you need to weigh your options. If you can’t assess different scenarios quickly to understand how each one would impact your business, you risk crippling your supply chain.

In the supply chain planning environment, agility often means the ability to quickly pivot to meet changing customer demands. When an organization cannot be responsive, they risk unfulfilled orders or sub-standard product quality. The ability to flex and change with market demands is a critical part of forward-thinking supply chain management DNA.

There’s a better way

There’s a better way

Add automation, deep insights, and agility to your planning — it’s called IBM Planning Analytics powered by IBM TM1®.

Spend more time on what matters

Instead of spending about 65 percent of your time in collecting data, you can automate much of the process. This enables you to focus on value-added planning, forecasting, reporting and analysis to deliver fast, optimized insights. Use one single planning solution wherein all your different lines of business can collaborate. This shared solution is dynamic and provides a single version of the truth across your organization. It’s accessible and the data is easy to interact with, reducing reliance on IT staff to help create and manage advanced models. The entire organization can use one tool to submit and analyze data and create accurate plans and forecasts. Choose from a range of visualization options to share informative scorecards, dashboards and reports with stakeholders.

Be an analytical captain on your data ocean

Remember that solution we mentioned? It’s not only ideal for collaboration, it’s great for analyzing a ton of data hosted on the IBM TM1 Server. This will give you the ability to integrate all of your data warehouses (CRM, ERP, etc.) to deliver a full picture of what’s going on in your supply chain. And it’s a pretty picture, at that. The simple, easy-to-use, self-service interface gives you the ability to analyze and visualize results and identify trends to inform decisions. The solution can identify insights automatically, directly from your data, to apply to the planning and analytics process. Plus, with everyone using the same solution, you limit the possibility of erroneous formulas and mismatched numbers. You also have the ability to perform complex dimensional analysis to go deep into your numbers and understand the implications of changes.

Be ready for anything

We all know plans change. But with the right tool, your plans can be automatically adjusted as needed to meet changing supply-demand requirements. This helps you react faster to changing market conditions or unexpected impacts on your supply chain. You can easily weigh your options and quickly conduct unlimited what-if scenario analyses to discover how to optimize business outcomes. Just a few clicks and you’ll see how one change will impact each part of your supply chain, including sales and profit modeling.

Gartner predicted that by 2020, at least 25 percent of large organizations will increase planning accuracy by integrating key operational planning processes with financial planning and analysis. 4

—Gartner Predicts 2018: SaaS Financial Management Applications Increase Integration, Automation and Sophistication, Gartner, 2017.

Why IBM?

Why IBM?

With IBM Planning Analytics, you can go beyond automation to optimize supply chain performance with advanced planning and forecasting capabilities. The solution is built to drive business success through lean operations, inventory optimization, material management, waste reduction and working capital optimization. And with this scalable solution available on premises or in the cloud, you can choose the deployment that fits your needs and scale up as your needs grow.

Plus, IBM Planning Analytics provides the ability to:

- Automate and streamline planning, budgeting and forecasting processes

- Perform unlimited what-if scenario analysis to take effective action

- Achieve real-time, detailed visibility into key inventory control and supply chain management metrics

- Perform complex multi-dimensional analysis and calculations

- Automatically create and deliver new insights directly from data for more reliable plans and forecasts

- Leverage an interactive, customizable planning and analytics workspace to measure and monitor performance, evaluate plans, identify gaps and diagnose root causes

- Have the option to work in the familiar Microsoft Excel interface with minimal learning curve while enjoying all the capabilities of a modern planning and analytics solution

Client stories

Client stories

You don’t have to take it from us – find out how our clients are succeeding with IBM Planning Analytics:

Allen Edmonds

IBM Planning Analytics is helping Allen Edmonds evolve into a smarter business to provide better service to customers and optimize inventory and costs.

Outcomes:

- 50 percent faster reporting, saving one day per week on weekly strategic planning

- 10 percent lift in forecasting accuracy

“ Our reporting processes are at least 50 percent faster now, which has a real positive impact on the way we do business. ”

–Connie Walsh, Director of Retail Inventory, Planning and Analysis, Allen Edmonds

Rotkäppchen-Mumm

IBM Planning Analytics to optimize the production of product quantities based on accurate insights into demand and future trends.

Outcomes:

- 22 percent increase in accuracy of selected sales forecasts

- Reduces stock levels without increasing the risk of stockouts

“ The ability to access IBM Planning Analytics from any device enables us to work on the move, spend more time with business users out in the field and work much more flexibly and productively. ”

– André Birrenbach, Chief Information Officer, Rotkäppchen-Mumm

Fleetpride

IBM Planning Analytics to give supply chain managers game-changing insights into operations. It has helped them to improve the efficiency of the entire supply chain.

Outcomes:

- 99.5 percent of warehouse packing tasks are now error-free

- Accelerates inventory movement, reducing labor costs and increasing revenues

“ Line managers all have quick, easy access to the latest operational data via detailed reports that help them to make smarter, more-informed decisions to improve the efficiency of the entire supply chain. ”

– Homarjun Agrahari, Director, Advanced Analytics, FleetPride

Next steps

Next steps

See if IBM Planning Analytics is right for you

Hungry for more? Explore all the features available to you.

See IBM Planning Analytics in action

Experience this interactive demo to get a real taste of functionality.

Download PDF

Download the PDF version of this white paper.

Sources

Sources

- Charles Sull, Donald Sull, Rebecca Homkes, "Why Strategy Execution Unravels -- and What to Do About It," Harvard Business Review, March 2015

- Keith Button, CFO Magazine article “FP&A – Let the Fun Begin”, Nov 2, 2017

- Forbes Insights “The Data Differentiator – How Improving Data Quality Improves Business” 2017

- Gartner Predicts 2018: SaaS Financial Management Applications Increase Integration, Automation and Sophistication, Gartner, 2017.